Powder/Granular bag random robot sorting collecting for pre-made bag packaging

PRODUCT DESCRIPTION

HP-600S Servo Type Fully Automatic Pillow Packaging Machine

Hot sale bread chocolate candy dumpling food packing equipment supplier automatic horizontal snack wafer biscuit meat personal care products toys pillow packing machines manufacturer Additional Optional Devices/Functions: Fully automatic non-stop fi...

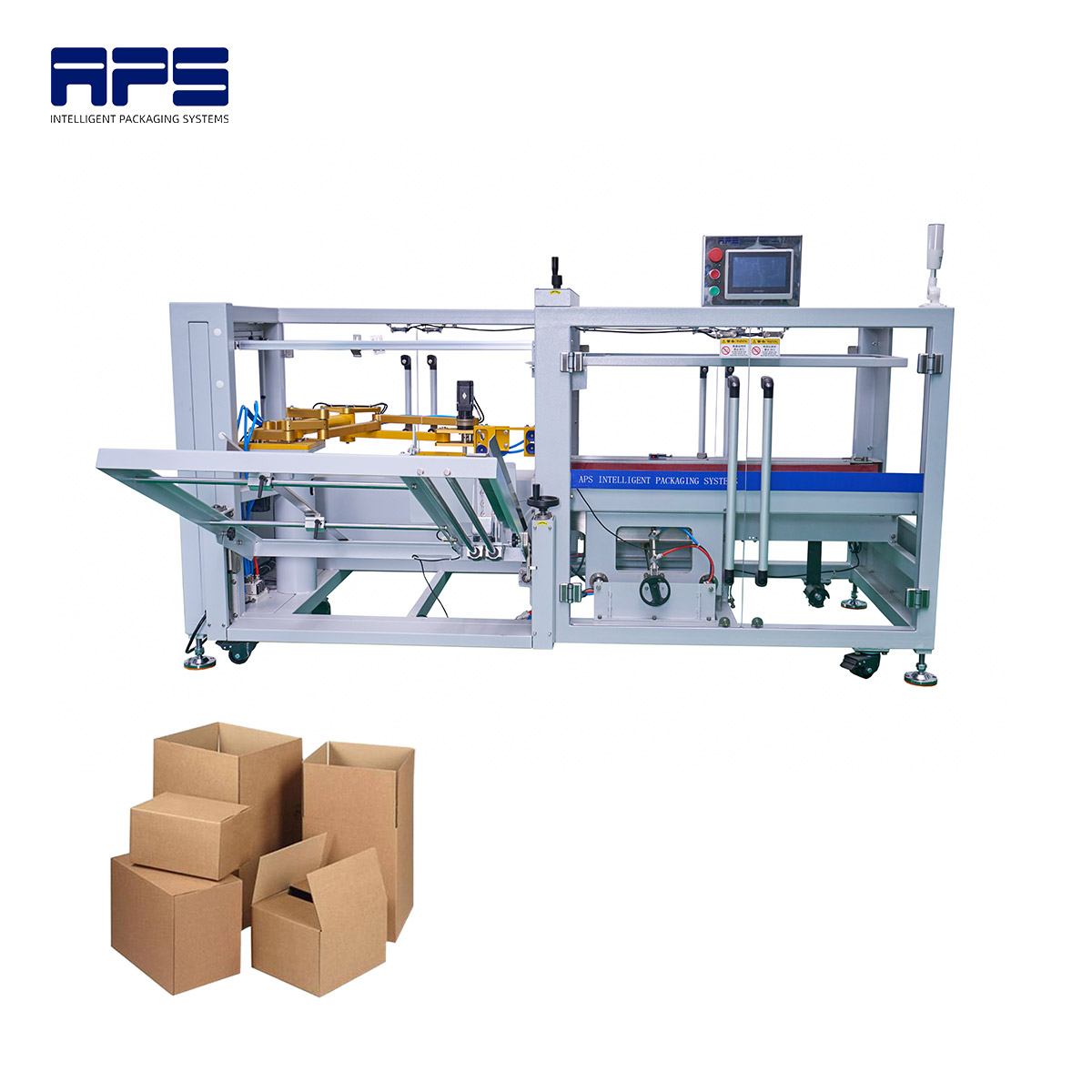

CE-S15 heavy-duty Vertical Carton Erector & Bottom Sealer

1. Work speed: 5-15 ctns/min. 2. Easy to control and high stability can reduce waste rate and saving costs; 3. Suitable for corrugated cartons of various sizes and special cartons; 4. Protector & safety doors can effectively protect employees; 5....

PR-165 Collaborative Robotic Palletizer

APS High-Load 165kg Industrial Palletizing Robot with Dual-Side Gripping for Cartons and Pallets 1. Operate on the left and right with cartons of different sizes at the same time. Loading capacity:165 kg. Max speed: times/min beat. Mixed grasping:...

CM-30H Servo-type Fully Automatic Vertical Cartoning Machine carton box packaging machine

Overview of technical performance advantages: The cardboard box has a wide range of sizes that can be accommodated. The maximum size that can be met is: Length: 6000mm, Width: 1800mm, Height: 1600mm. High-end configuration: The entire machine adopts ...

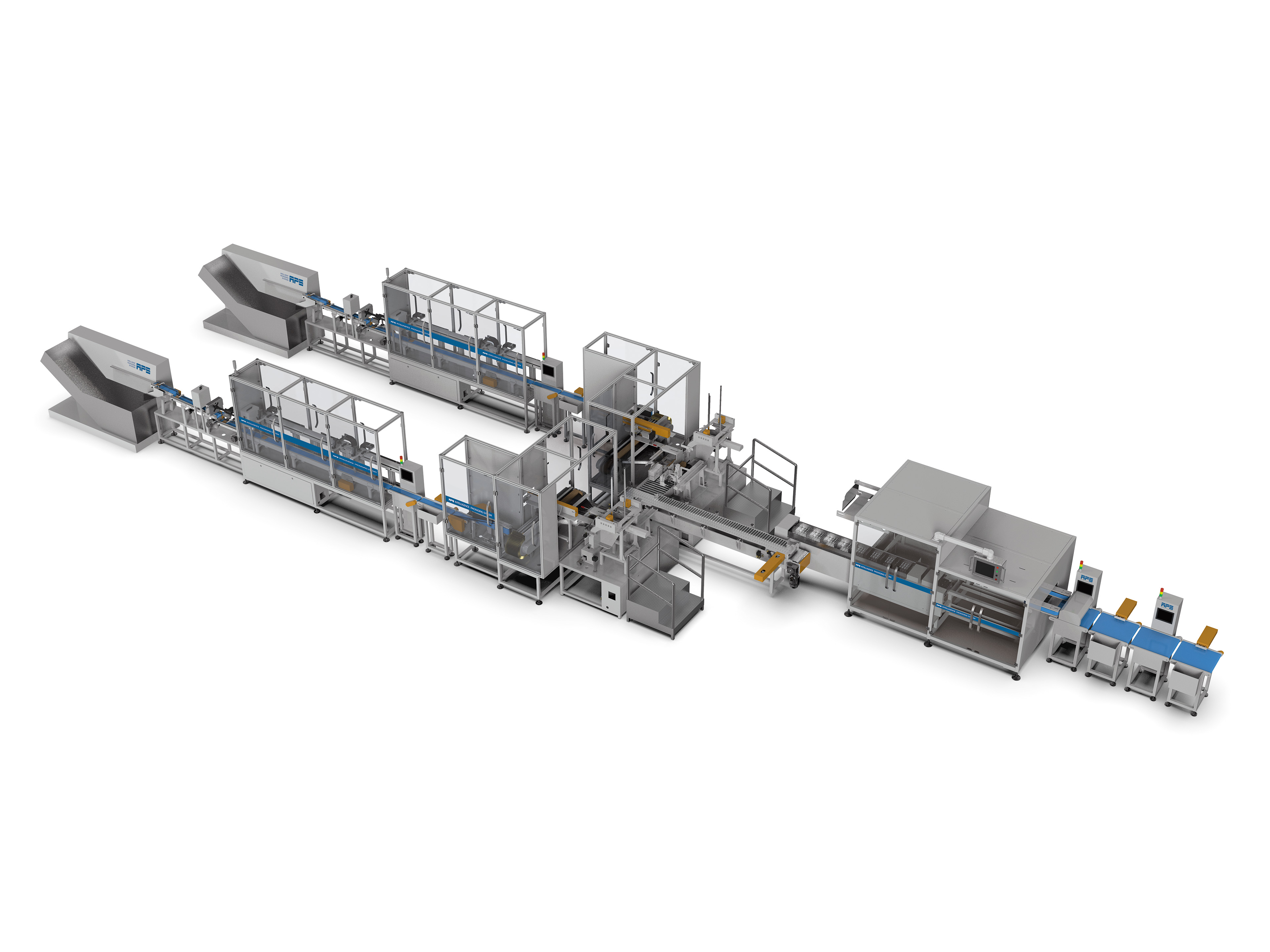

powder granule bag pouch random orienting machine distribution tray packaging palletizing line

Production process diagram: Functional units of the entire packaging production line: Image ID 03A Users can choose to configure the device via connection: 2D machine vision system, pillow packaging machine, pre-made bag packaging machine, metal dete...

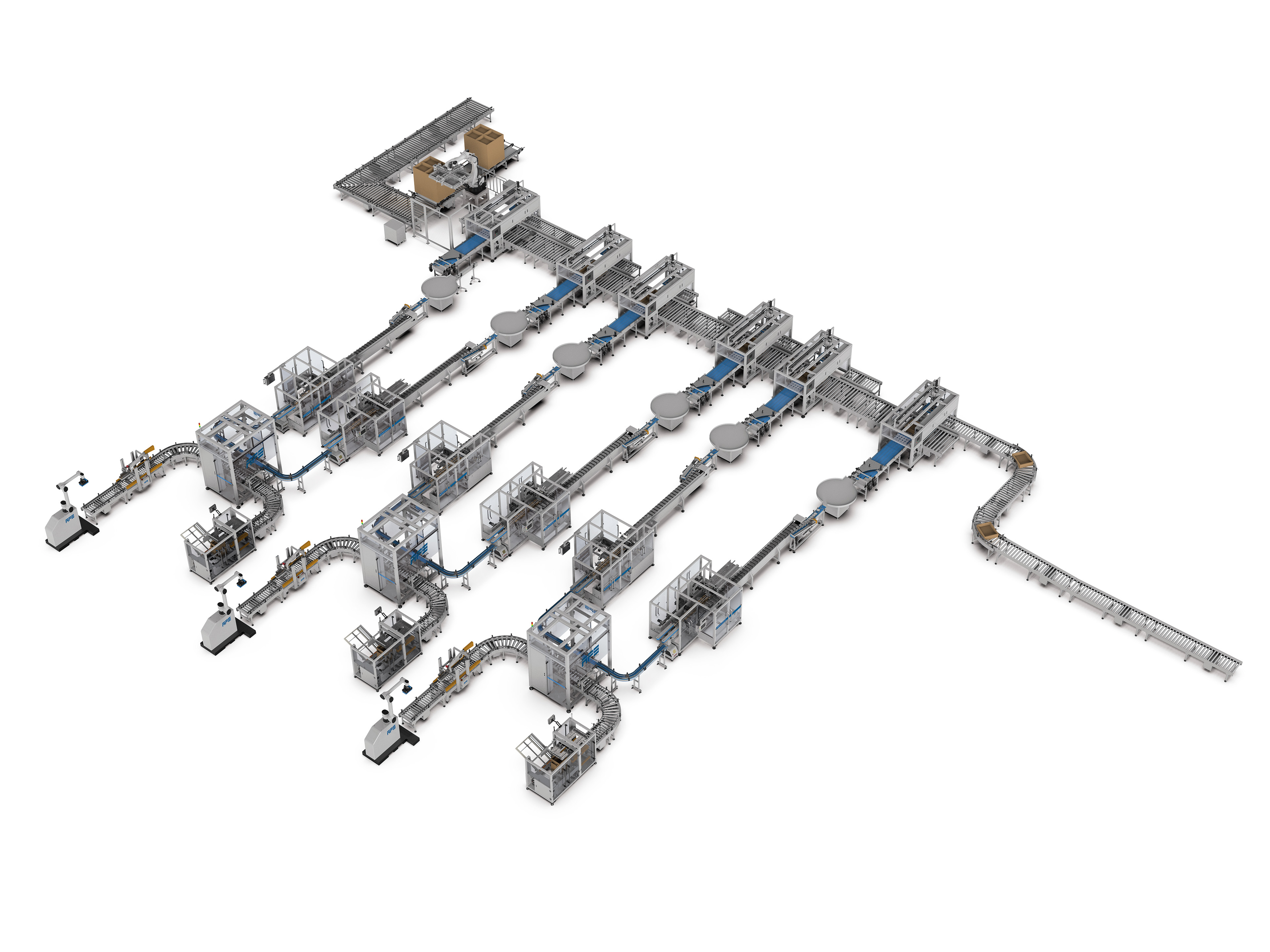

Medical Infusion Bags Packaging, Boxing, and Palletizing

Production process diagram: Pillow-type packaging → Unpacking → Partitioned packing → Packing → Sealing → Palletizing Functional units of the entire packaging production line: Image ID 15A Users can choose to configure the device via connec...

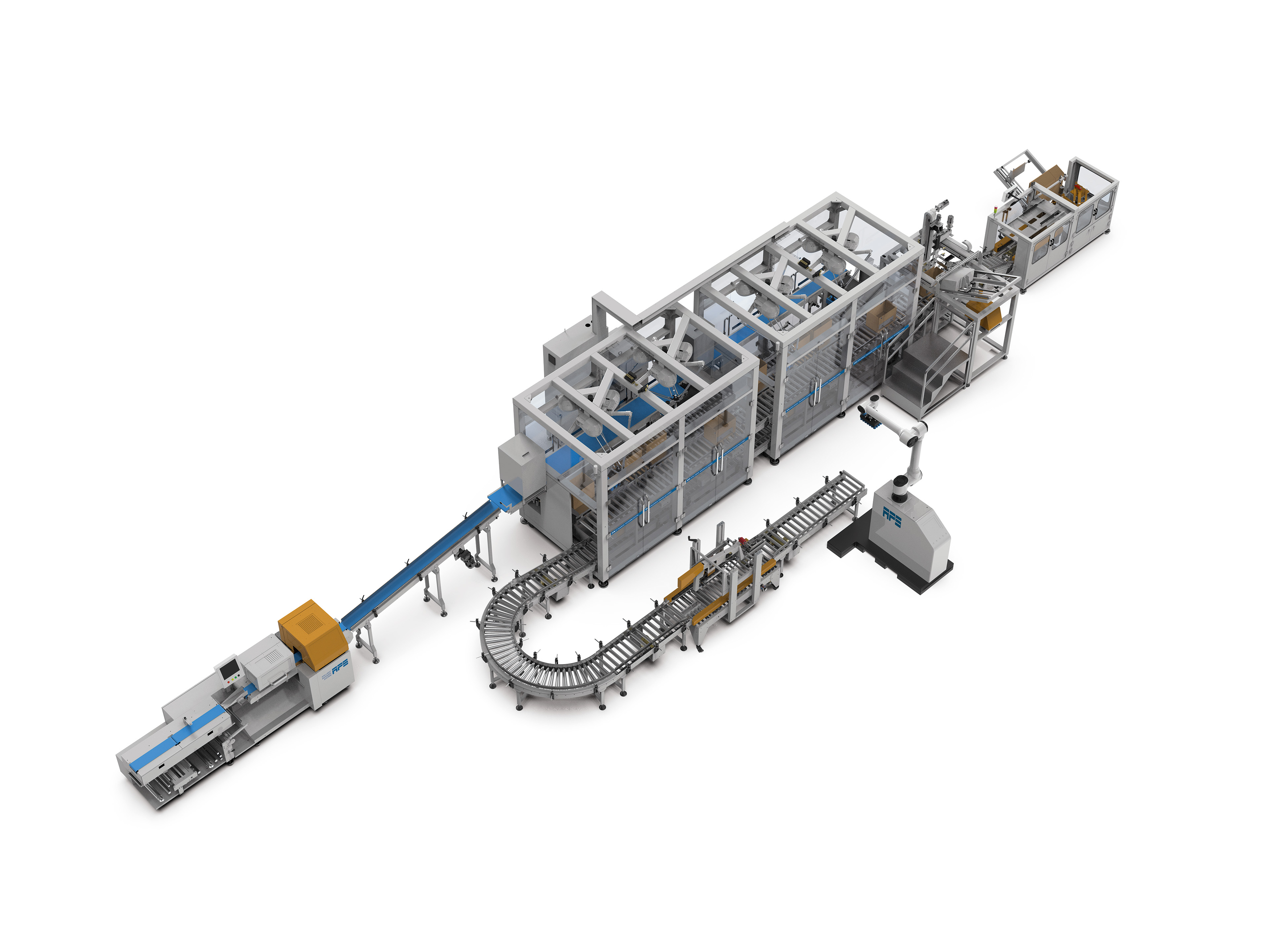

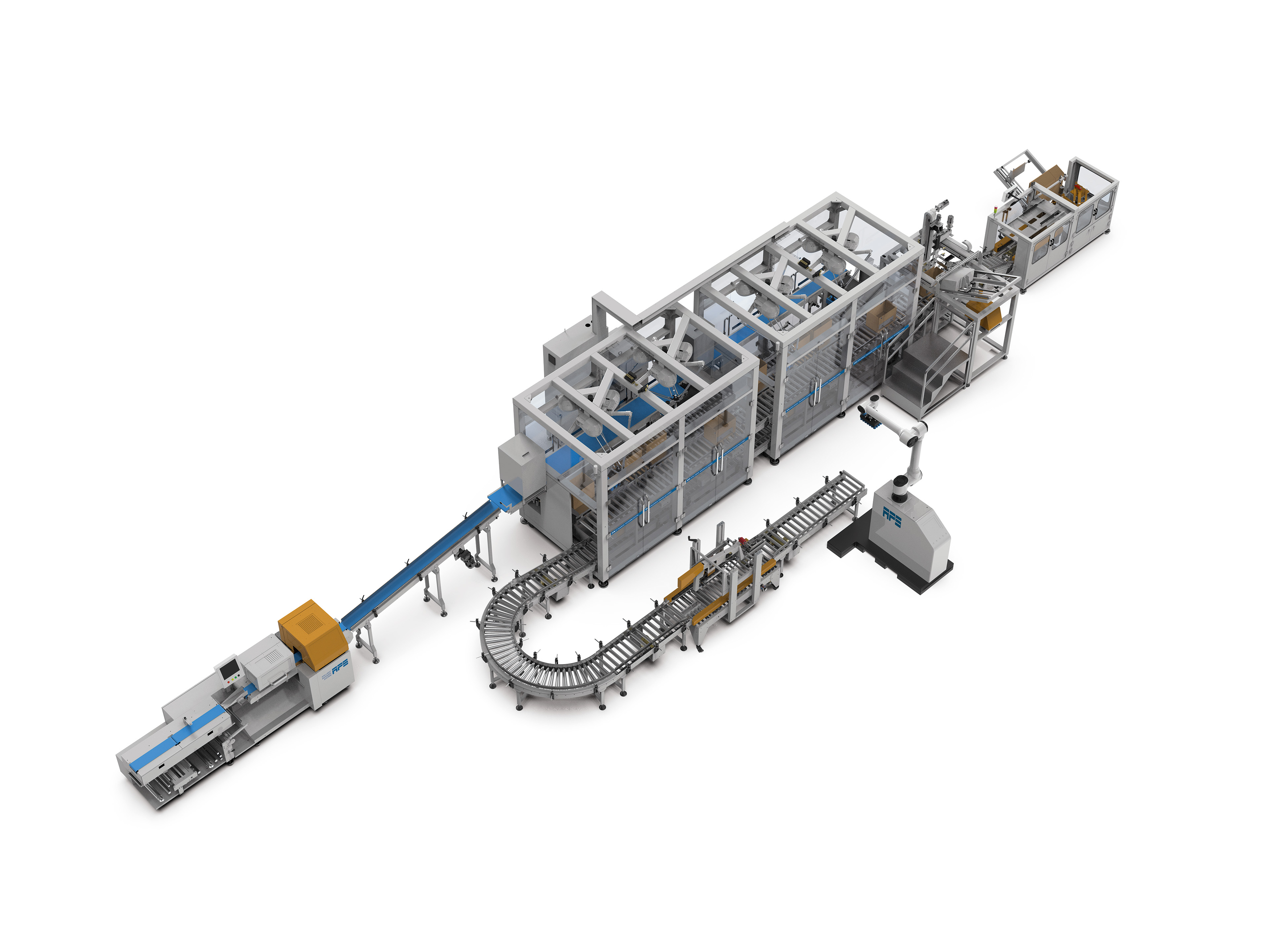

Pillow-Pack Ice Cream Products: Packaging, Boxing, and Palletizing

Production process diagram: Material handling → Packaging → case packaging → Robot packing → Sealing → Palletizing Functional units of the entire production line: Image number 12A Users can choose to configure the device via connection: Ther...

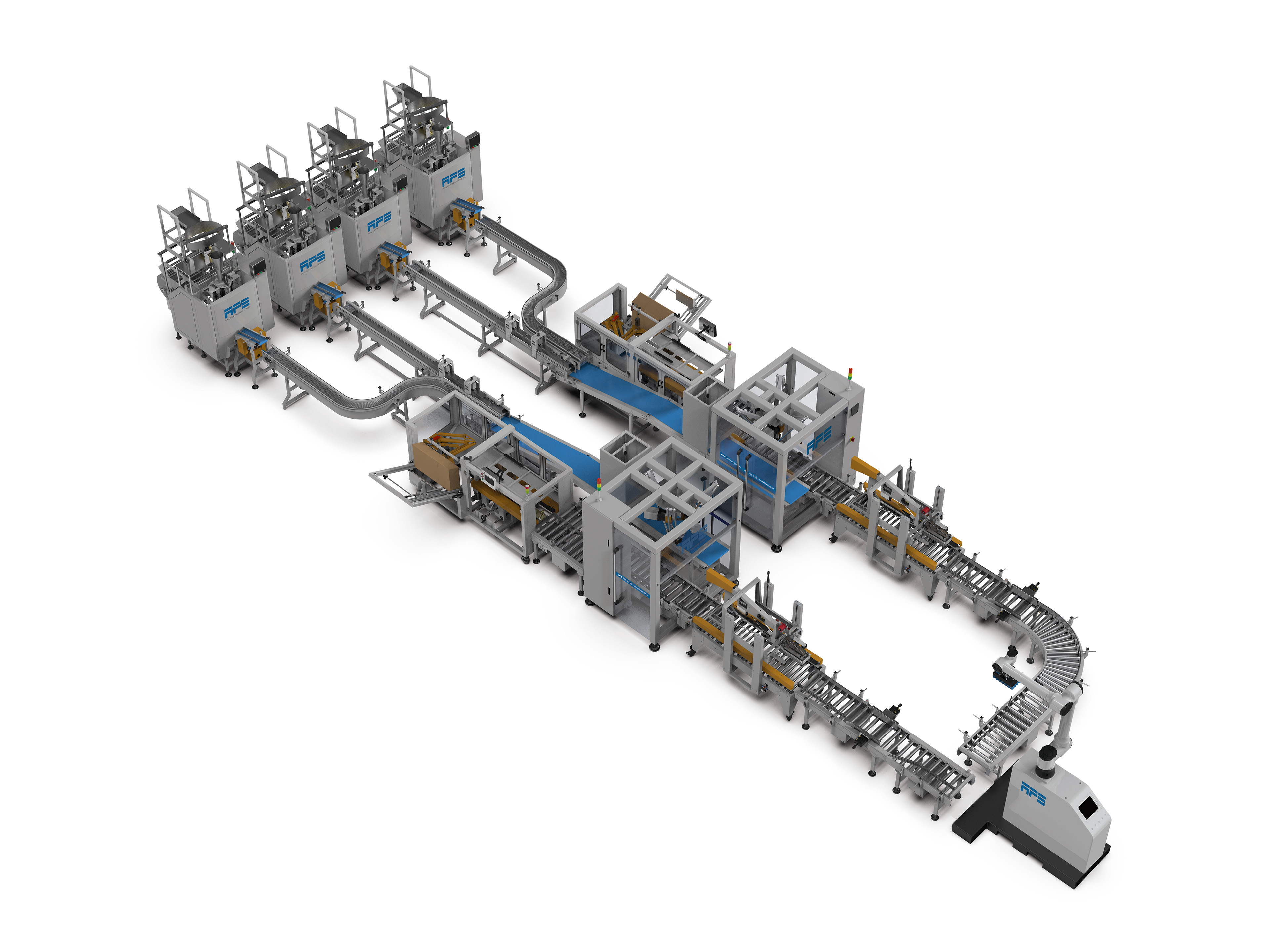

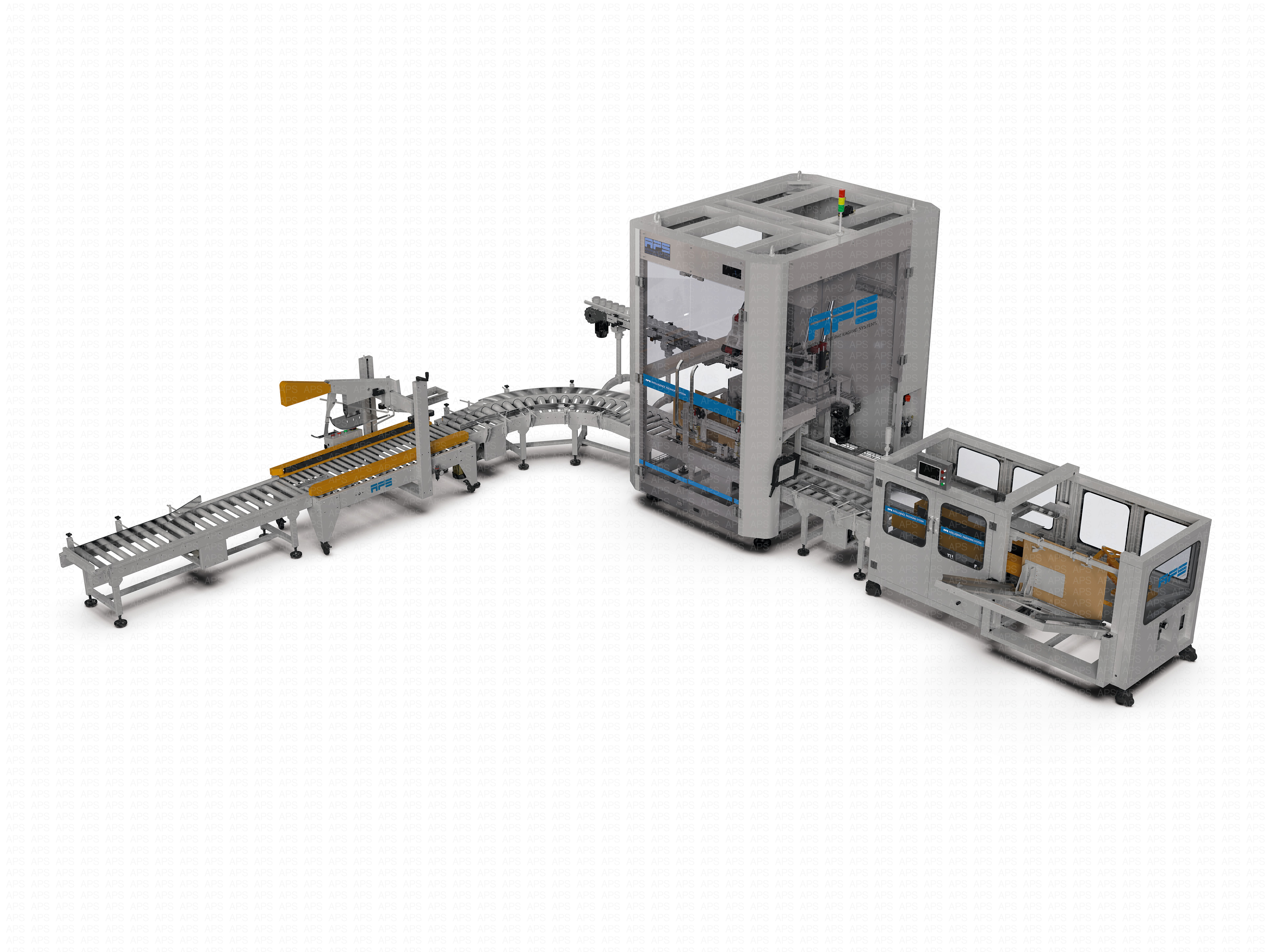

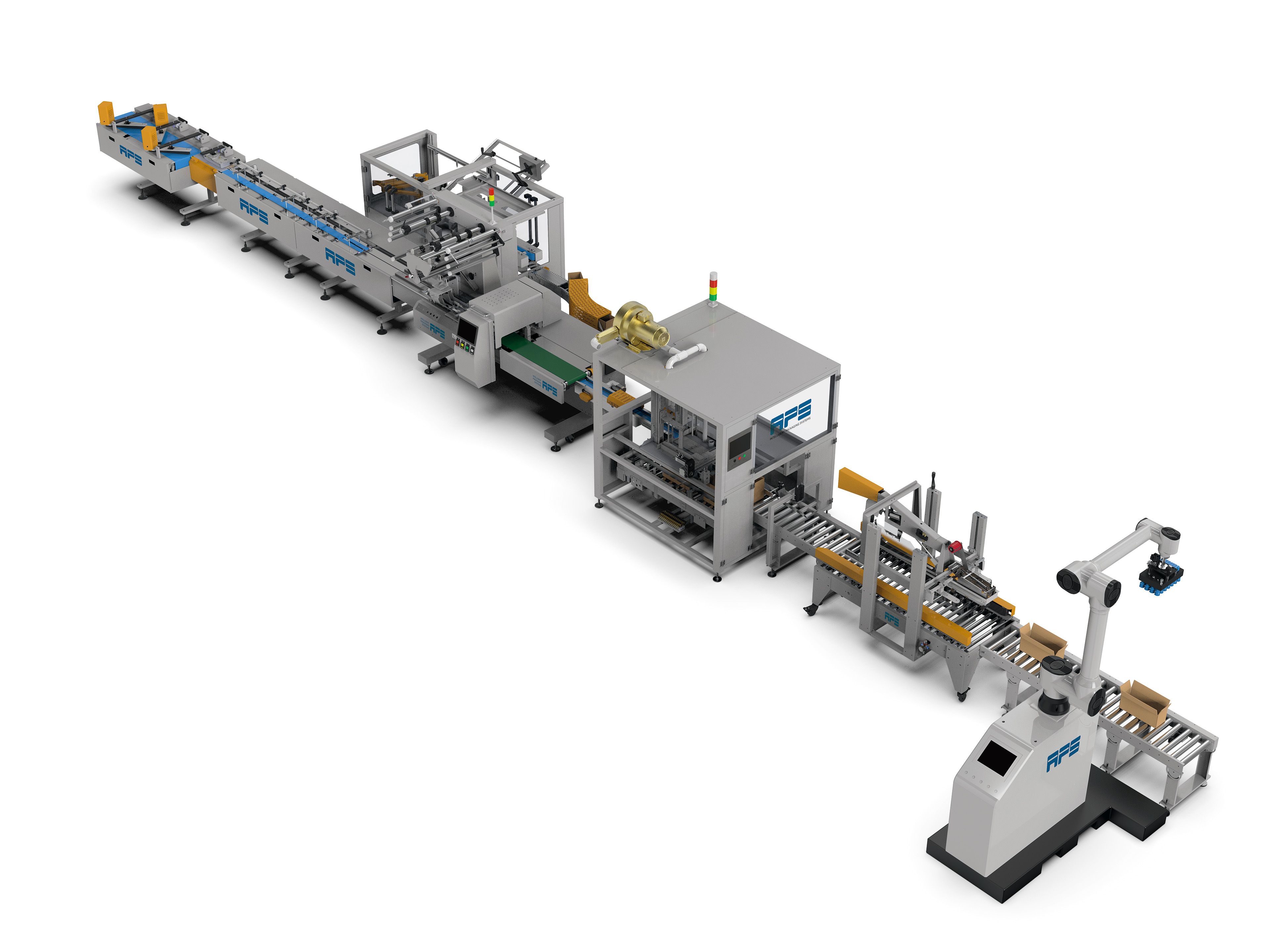

carton box automatic collecting case packaging palletizing line

Overview of technical performance advantages: Modular design: The feeding conveyor points can be organized and buffered to configure various feeding systems according to different user product speed requirements, adapting to more users' diverse fully...

Flexible Bag Packaging Products visual detection Conveying, Boxing, and Palletizing

Production process diagram: Packaging → Metal Detection → Weight Detection → Flattening and Assembly → Visual Positioning → Unpacking → Robot Packing → Sealing → Palletizing Functional units of the entire packaging production line: Im...

CE-R40 robotic hand high speed case erector

1. Maximum speed 25 boxes per minute . 2. Easy to control and high stability can reduce waste rate and saving costs; 3. Suitable for corrugated cartons of various sizes and special cartons; 4. Protector & safety doors can effectively protect empl...

PR-50 collaborative robot palletizer

1. Operate on the left and right with cartons of different sizes at the sametime. Loading capacity:50 kg. Max speed: 10 times/min beat.Mixed grasping.15-16 CTNS/min. 2. lt can be freely set with different speeds and quantities. Easy to control. 3. Th...

Cup Products Conveying, Sorting, Packing, and Palletizing

Cup Ice Cream Products Packaging production line layout display: Image ID 01 Production process diagram: Material handling → Packaging → Unpacking → Robot packing → Sealing → Palletizing Functional units of the entire packaging production l...

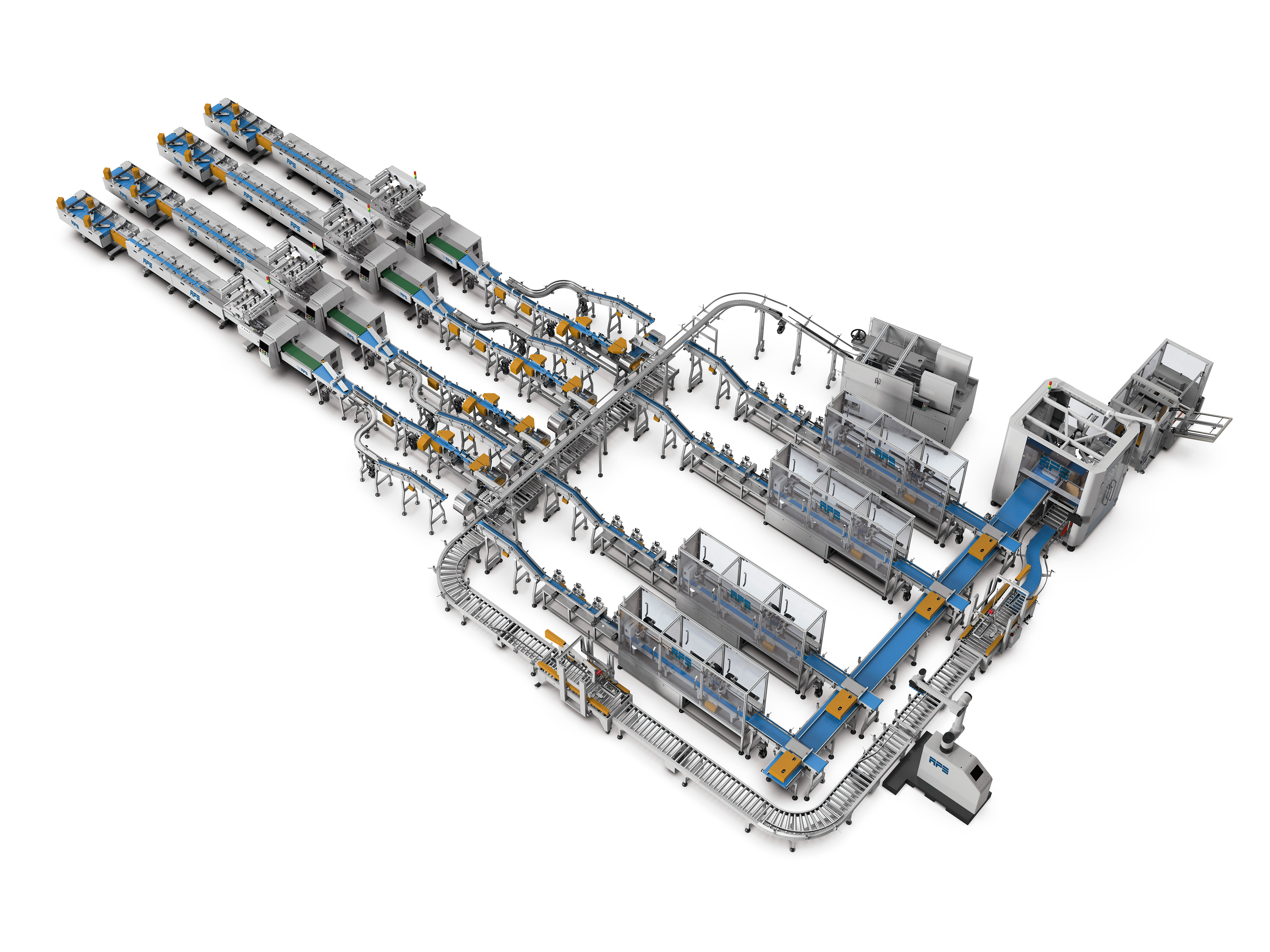

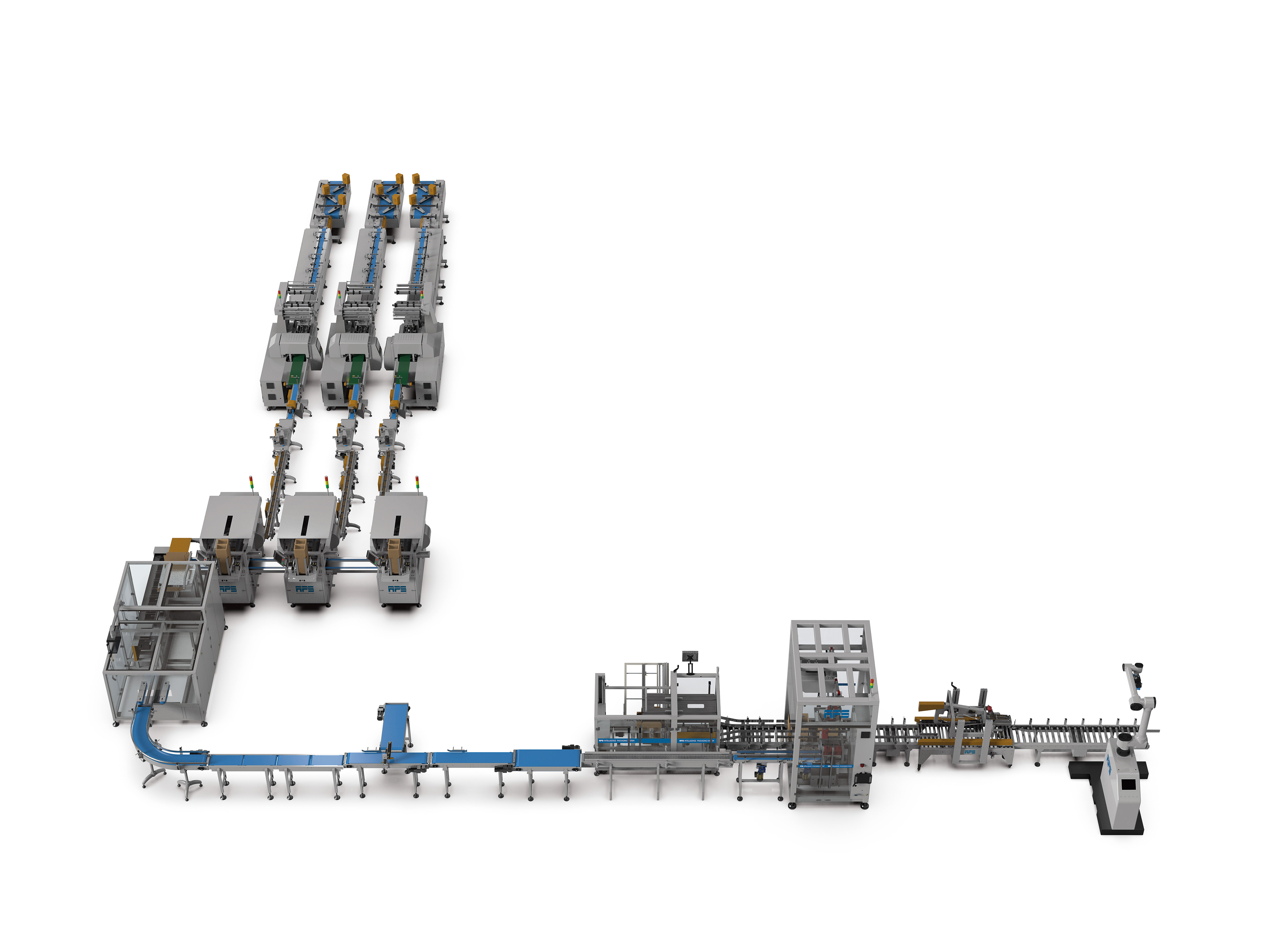

baking food 2-in-1 fully automatic single package sorting collecting bagging case packing palletizing line

Production process diagram: Process 1: Material handling line → Pillow packaging machine packaging → Secondary material handling → Intermediate packaging → Unpacking → Packing → Sealing → Palletizing Process 2: Material handling line ...

Steamed Rice Cake Bowl depalletizing Feeding carton box packaging case packing and Palletizing

Functional units of the entire packaging production line: Image ID 08A Users can choose to configure the device via connection. Metal detector rejection machine, weight detection rejection machine, inkjet printer, carton labeling machine Overview of ...

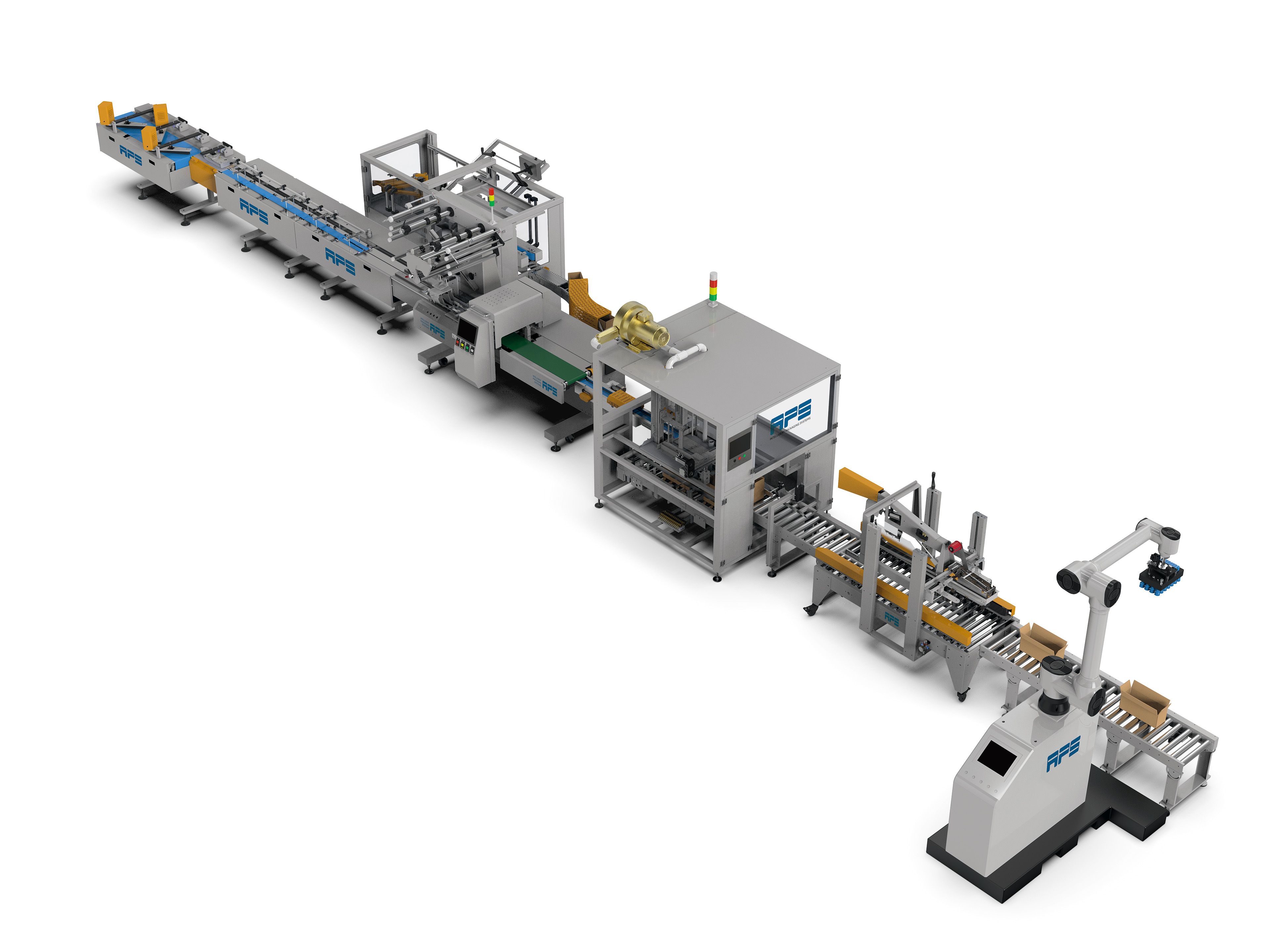

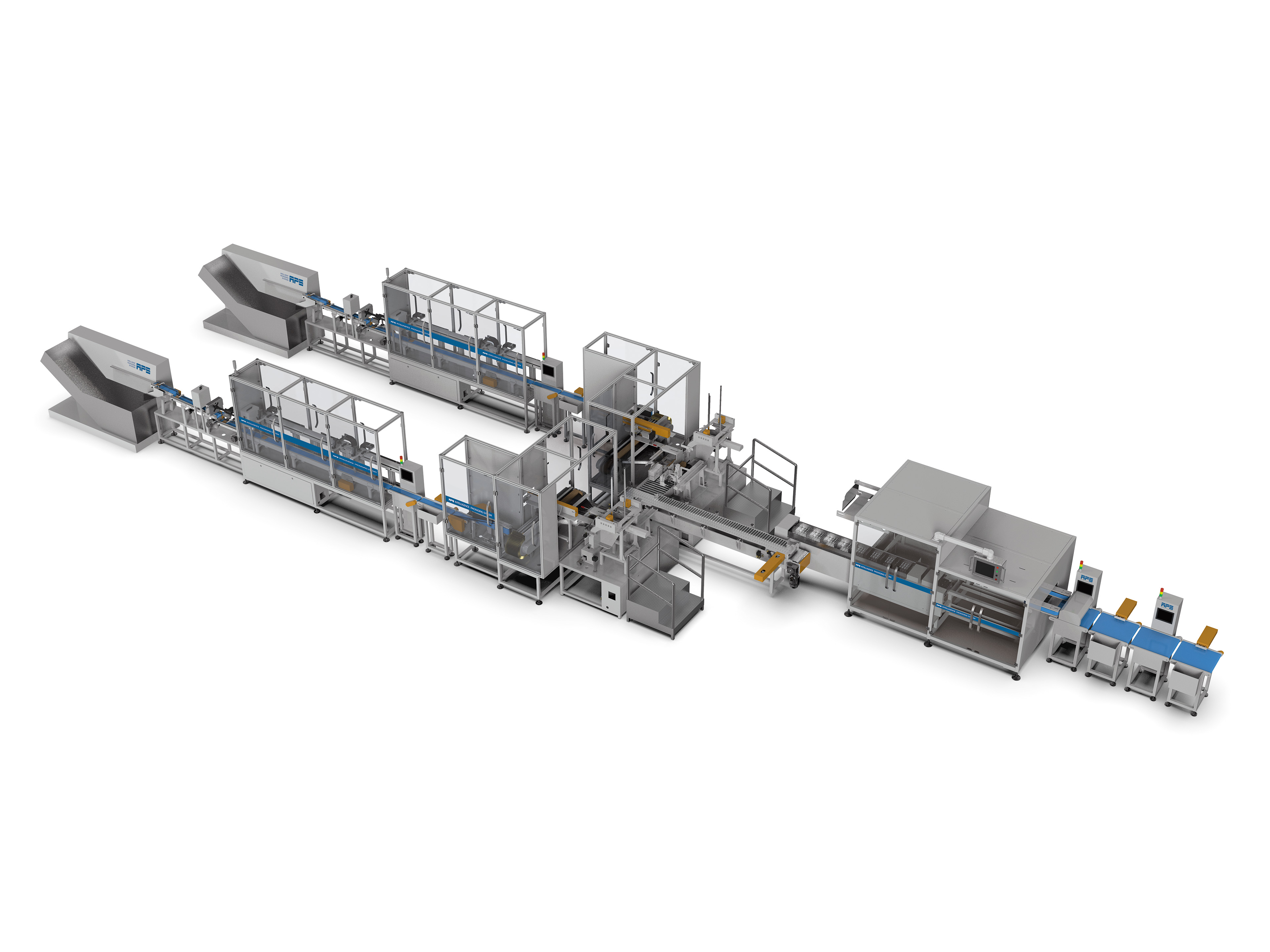

Fully Pillow-Pack Biscuits: Conveying, Sorting, Counting, tray packing , carton box packaging case packaging and Palletizing

Functional units of the entire packaging production line: Image ID 08A Users can choose to configure the device via connection. Metal detector rejection machine, weight detection rejection machine, inkjet printer, carton labeling machine Overview of ...

PR-30 Collaborative Robotic Palletizer

APS Automatic warehouse pallet robot 6 axis industrial cobot 10kg 20kg 30kg robotic palletizer collaborative robot carton case bag collaborative robot palletizer stacking machine 1. Operate on the left and right with cartons of different sizes at the...

CS-D15 case sealing machine

Device Name Folding type fully automatic box sealing machine Equipment standard version model CS-D15 Servo system configuration standards Inovance Meet the production product types Meet the needs of the entire industry Device dimensions long:L1760mm ...

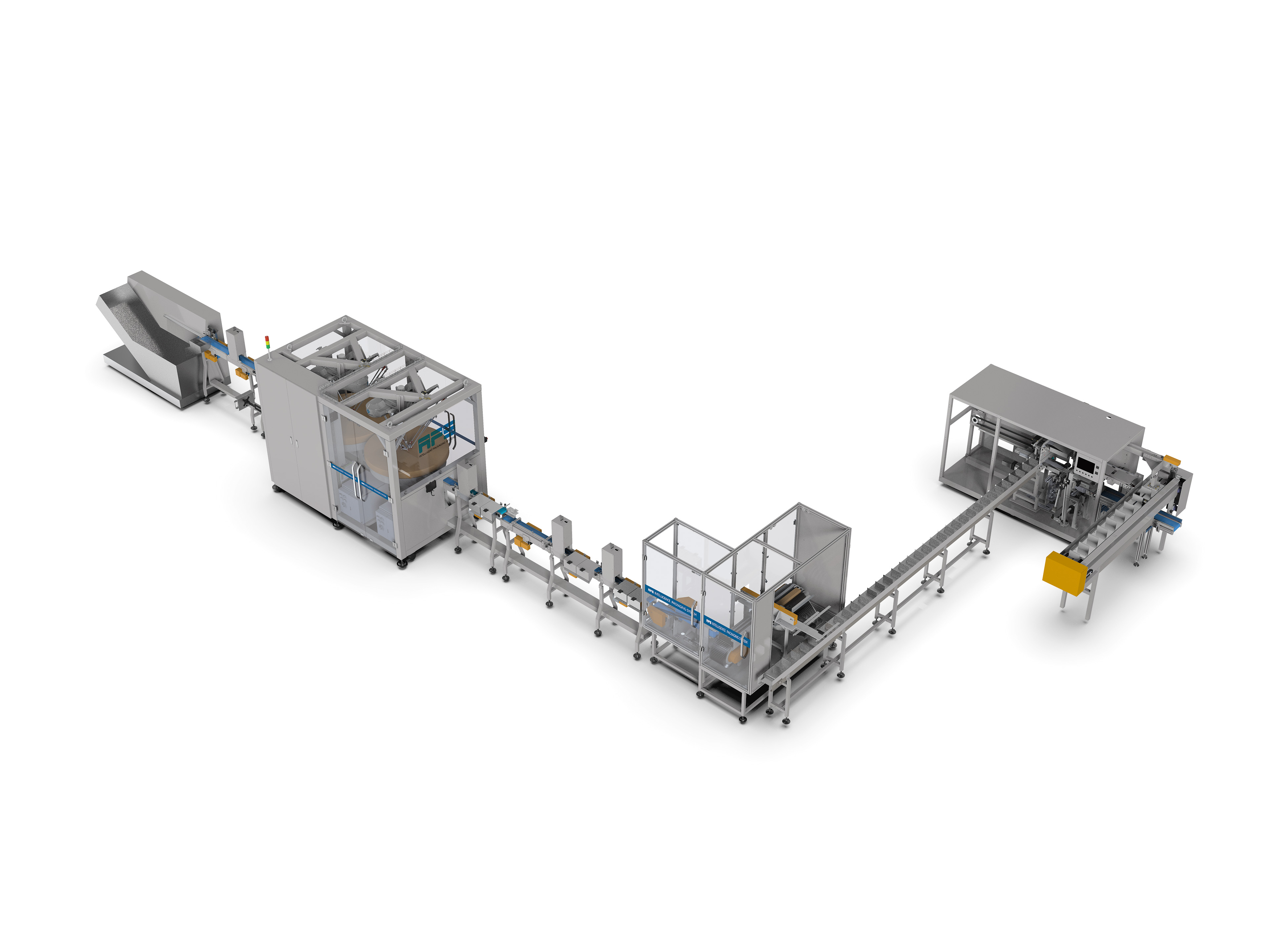

Powder/Granular bag random robot sorting collecting for pre-made bag packaging

Production process diagram: Material handling → Visual inspection → Turning over → Visual inspection → Turning over 2 times → Visual inspection → Palletizing → Side-standing collection → Palletizing → Intermediate packaging Functional...

HP-600S Servo Type Fully Automatic Pillow Packaging Machine

Hot sale bread chocolate candy dumpling food packing equipment supplier automatic horizontal snack wafer biscuit meat personal care products toys pillow packing machines manufacturer Additional Optional Devices/Functions: Fully automatic non-stop fi...

CE-S15 heavy-duty Vertical Carton Erector & Bottom Sealer

1. Work speed: 5-15 ctns/min. 2. Easy to control and high stability can reduce waste rate and saving costs; 3. Suitable for corrugated cartons of various sizes and special cartons; 4. Protector & safety doors can effectively protect employees; 5....

PR-165 Collaborative Robotic Palletizer

APS High-Load 165kg Industrial Palletizing Robot with Dual-Side Gripping for Cartons and Pallets 1. Operate on the left and right with cartons of different sizes at the same time. Loading capacity:165 kg. Max speed: times/min beat. Mixed grasping:...

CM-30H Servo-type Fully Automatic Vertical Cartoning Machine carton box packaging machine

Overview of technical performance advantages: The cardboard box has a wide range of sizes that can be accommodated. The maximum size that can be met is: Length: 6000mm, Width: 1800mm, Height: 1600mm. High-end configuration: The entire machine adopts ...

powder granule bag pouch random orienting machine distribution tray packaging palletizing line

Production process diagram: Functional units of the entire packaging production line: Image ID 03A Users can choose to configure the device via connection: 2D machine vision system, pillow packaging machine, pre-made bag packaging machine, metal dete...

Medical Infusion Bags Packaging, Boxing, and Palletizing

Production process diagram: Pillow-type packaging → Unpacking → Partitioned packing → Packing → Sealing → Palletizing Functional units of the entire packaging production line: Image ID 15A Users can choose to configure the device via connec...

Pillow-Pack Ice Cream Products: Packaging, Boxing, and Palletizing

Production process diagram: Material handling → Packaging → case packaging → Robot packing → Sealing → Palletizing Functional units of the entire production line: Image number 12A Users can choose to configure the device via connection: Ther...

carton box automatic collecting case packaging palletizing line

Overview of technical performance advantages: Modular design: The feeding conveyor points can be organized and buffered to configure various feeding systems according to different user product speed requirements, adapting to more users' diverse fully...